In the early 1990s, standards were created to assess the compliance of protective gloves with the requirements of legislation. Each standard corresponds to a risk and is identified by a unique reference code. It allows users to purchase the gloves that will protect them against the right risk or risks.

Table of contents

What are EN Standards?

EN represents European standards which provide businesses and individuals with a common basis, allowing to compare the products the ones with the others. They increase the visibility and understanding of the products among manufacturers inside and outside the European territory. A standard is a technical specification defining requirements for products, production processes, services, or test-methods.

In order to be recognized as a European standard, the technical standard has to be ratified by one of the three recognized European Standardization Organizations (ESOS) which are the European Committee for Standardization CEN, the European Committee for Electrotechnical Standardization CENELEC and the European Telecommunications Standards Institute ETSI. The EN standards are designed and created through a transparent, open, and consensual process.

What do different EN Standards mean?

EN 420: The general standard

First of all, EN 420 was put in place to centralize all the general requirements: the design of the gloves, the harmlessness of the materials, the cleaning management methods, the requirement for comfort and size, and glove marking methods as well as the instructions for drafting the user manual. It is currently under revision and will now be called EN ISO 21420. The EN 420 standard basically proves that the gloves will not be a harm to the user and that they are comfortable to wear.

A glove that meets this standard alone is therefore not a personal protective equipment (PPE), as it does not protect against any particular risk.

To be effective against one or more risks, this standard must be combined with the other ones.

EN 388: The standard against mechanical hazards

The EN 388 standard is the European protective gloves standard against mechanical hazards. The most recent version of it is the EN 388:2016+A1:2018 and it has been published in December 2018.

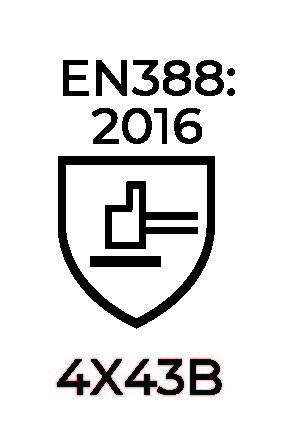

Accredited products are marked with the EN 388:2016 pictogram. Below this icon will be 4 numbers and 1 or 2 letters, which indicate the test performance of the gloves against each hazard:

This standard tests, firstly, abrasion resistance (on a scale of 1 to 4): the material is subjected to abrasion by sandpaper under a determined amount of pressure.

Then, blade cut resistance (on a scale of 1 to 5) is also tested: this involves a rotating circular blade moving horizontally through the sample material.

After that, the tear resistance (on a scale of 1 to 4) is tested: this involves finding the force required to tear the glove material apart, as well as the puncture resistance (on a scale of 1 to 4), which result is based on the amount of force required to puncture the material with a tip.

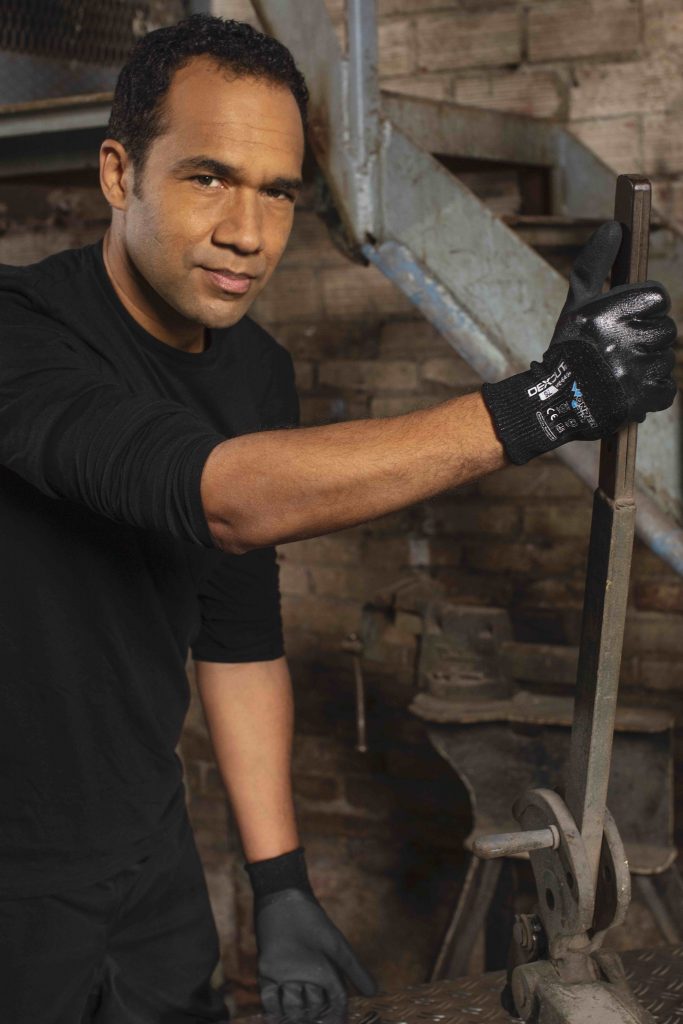

All our protective gloves at Wonder Grip® have an EN 388 score: for instance, the WG-640+ Dexcut has a EN388:2016 score of 4342C. It therefore offers an excellent cut protection while combining it with an outstanding flexibility, dexterity and grip.

EN 407: The standard against thermal hazards

The EN 407 standard is the European protective standard regarding resistance to the thermal hazards which are heat, flames, and fire.

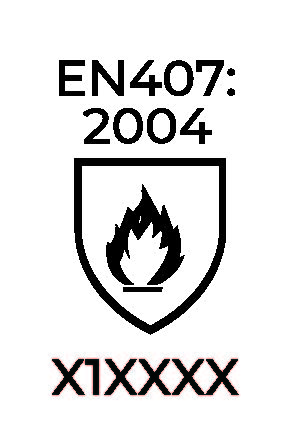

Accredited products are marked with the EN 407 pictogram. Below this icon will be 6 numbers which indicate the test performance of the gloves against each hazard:

Firstly, this standard tests, on a scale of 1 to 4, the resisted duration to flame persistence: this is based on the length of time the material continues to burn and glow after the source of ignition is removed.

Then, the resistance to contact heat is tested: it is based on the temperature range (100-500°C) at which the user will feel pain for at least 15 seconds.

Furthermore, the resistance to convective heat is tested: this test is based on the length of time the glove is able to delay the transfer of heat from a flame.

Then, the resistance to radiant heat is tested: this is measured with the length of time the glove is able to delay the transfer of heat when exposed to a radiant heat source.

After that, the resistance to small projections of molten metal is tested: this is measured with the number of molten metal drops that are required to heat the glove to a given level, from under 5 drops to under 35 drops.

Finally, the resistance to large splashes of molten metal is tested, and this test determines the weight of molten metal that is required to cause smoothing or pin holing across a simulated skin placed directly behind the glove sample, from 30g to 200g.

At Wonder Grip®, some of our protective gloves have been tested against contact heat, such as the WG-633 Dexcut®,which has an EN 407 score of X2XXX, combined with a double protection against cut and cold.

EN 511: The standard against cold hazards

The EN 511 Standard is the European protective standard regarding resistance to cold and water.

Accredited products are marked with the EN 511 pictogram. Below this icon will be 3 numbers which indicate the test performance of the gloves against each hazard:

This standard tests, firstly, the resistance to convective cold (on a scale of 1 to 4). This is measured by the electrical power required to maintain a constant temperature gradient between the surface of the heated hand and the atmosphere of an environmental chamber cooled down to 20°C.

The resistance to contact cold (on a scale of 1 to 4) is also tested. The thermal resistance is calculated by placing the glove material between two metal plates which are at different temperatures.

Finally, the water permeability is tested: it is a simple pass/fail test during which the glove is submerged in water for 5 minutes. If the glove retains its permeability, then it passes with a level 1 rating, while the gloves that fail receive a level 0 rating.

At Wonder Grip®, some of our protective gloves have been tested against contact cold, such as the WG-538 FREEZE FLEX PLUS which has an EN 511 score of X2X, ensuring that your hands are kept warm down to -20°C.

EN 374: The standard against chemical hazards

The EN 374 standard is the European protective standard regarding resistance to chemical risks.

Accredited protection gloves are marked with the EN 374-2 and 374-3 pictograms.

With EN 374 -2, the penetration is tested. This means that in order to pass, the glove must not leak when tested with an air and water leak test. This involves either pressurizing the inside of the glove with air and detecting bubbles that are released from the glove or filling the glove with water and detecting drops on the outside of the glove.

With EN 374- 3, the permeation is tested. This means that the resistance to three chemicals chosen at random is tested by placing a patch on the outside of the glove to determine how long it takes chemicals to permeate the material, from more than 10 minutes to more than 480 minutes.

At Wonder Grip®, some of our protective gloves are resistant against chemicals, such as our OP-600L OPTY™, which offers an excellent grip in every environments (dry, oily or humid).

Other standards for protective gloves

What is the standard for food contact?

This standard makes it possible to certify that the safety gloves are suitable for food contact use. Food Contact Materials (FCMs), including gloves, must be sufficiently inert so that their constituents neither adversely affect consumer health nor influence the quality of the food. The safety of an FCM is evaluated by the European Food Safety Authority (EFSA) with two methods:

To start with, the standard ensures that the product formulation only contains substances listed by the EU regulation.

Then, migration tests are performed to ensure that the article in contact with food does not leach anything into the food.

If both of these tests are passed, the following symbol can be applied:

At Wonder Grip®, we offer protective gloves compatible with food contact, such as our WG-338W THERMO PLUS DOUBLE which is also cold resistant and 100% waterproof.

What are ANSI Cutting Standards?

The ANSI Cutting Standard is the American one against cut hazards.

American National Standards Institute (ANSI) has created a hand protection classification standard using a single testing method to determine cut resistance. The ANSI/ISEA testing methods give all personal protective equipment manufacturers a standard for rating products, which makes purchasing these items easier for the customer. In fact, In the United States, workers are required by OSHA law to ‘base the selection of the appropriate hand protection on an evaluation of the performance characteristics of hand protection relative to the tasks performed, conditions present, duration of use, and the hazards and potential hazards identified’.

This standard includes 9 classifications, from light cut hazards (200-499 grams to cut) for the A1 classification, to very high cut hazards (6000+ grams to cut) for the A9 classification. The single method has been selected to ensure all gloves receive the same level of protection in a given class. To determine cut levels, each glove is tested against a circular blade and the number of rotations required to cut through the same area of fabric is measured.

At Wonder Grip®, some of our protective gloves are tested by the ANSI/ISEA standard, such as our WG-795 DEXCUT®, which is also provides unparalleled flexibility and comfort.

The standards make it possible to check that the glove you want to use gives a good protection against the risk you want to mitigate, so it is essential to pay attention to reading these different standards.

On our website you will find a guide to help you find you perfect fit!

Do you want to know more about cut protective gloves in particular?

Do you want to know more about hand injuries at work?