Our priorities

1

Commitment to a CSR approach that make people and their environment our first concern

2

Manufacturing products that conform to the highest level of international standards

3

Permanently guaranteeing increased safety and comfort for all our users

4

Innovating every day, to redefine the notion of hand protection

Quality certification

Wonder Grip: quality guaranteed

Wonder Grip’s factories are ISO 9001, ISO 14001 and ISO 45001 certified. All manufacturing processes – from the purchase of raw materials to final product quality control – conform to the strictest of international standards.

ISO 9001

Our ISO 9001 certification means that our organisation satisfies all prerequisite conditions for an efficient and appropriate quality management system.

Wonder Grip’s policy towards continuous improvement enables us to guarantee that our products are manufactured according to strict quality requirements.

ISO 14001

ISO 45001

Wonder Grip was awarded ISO 45001 accreditation thanks to its commitment to building a greener future, respectful of the safety and the well-being of all its staff members and their families.

WONDER GRIP IS COMMITTED TO ENHANCING ITS PRODUCTION PROCESSES,

IN ORDER TO FURTHER REDUCE ITS ENVIRONMENTAL IMPACT

AND STRIVES PERMANENTLY TO DEVISE PRODUCTS SUITED TO THE MOST SENSITIVE OF SKIN TYPES.

REACH

Wonder Grip certifies that all the raw materials used in the manufacture of its products conform to European Union regulations (regulation n°1907/2006): regulation for chemical products and their use’, referred to as REACH (Registration, Evaluation, Authorisation and Restriction of Chemicals). The key aim of this directive is to offer the utmost level of protection and safety for human health and the environment.

Wonder Grip certifies that all the raw materials used in the manufacture of its products conform to European Union regulations (regulation n°1907/2006): regulation for chemical products and their use’, referred to as REACH (Registration, Evaluation, Authorisation and Restriction of Chemicals). The key aim of this directive is to offer the utmost level of protection and safety for human health and the environment.

OEKO-TEX®

Wonder Grip strives to constantly offer its clients more added value. One of the main reasons that spurred us to request this certification was so that we could demonstrate that Wonder Grip stands out from its competitors thanks, not only to the technical quality of its products, but also to the intrinsic quality of the raw materials used. Whereas certain competitors continue to use toxic solvents, which are a hazard for production line operators and end product users, Wonder Grip’s difference lies in its OEKO-TEX® accreditation.

Wonder Grip strives to constantly offer its clients more added value. One of the main reasons that spurred us to request this certification was so that we could demonstrate that Wonder Grip stands out from its competitors thanks, not only to the technical quality of its products, but also to the intrinsic quality of the raw materials used. Whereas certain competitors continue to use toxic solvents, which are a hazard for production line operators and end product users, Wonder Grip’s difference lies in its OEKO-TEX® accreditation.

Wonder Grip Accreditation No.17.HCN.14623

Accreditations

SEDEX Member

Sedex is a global membership organisation that prides itself on simplifying trade for the benefit of all. Our work is focused on making it easier for our members to trade in a way that benefits everyone.

SMETA 4-PILLAR

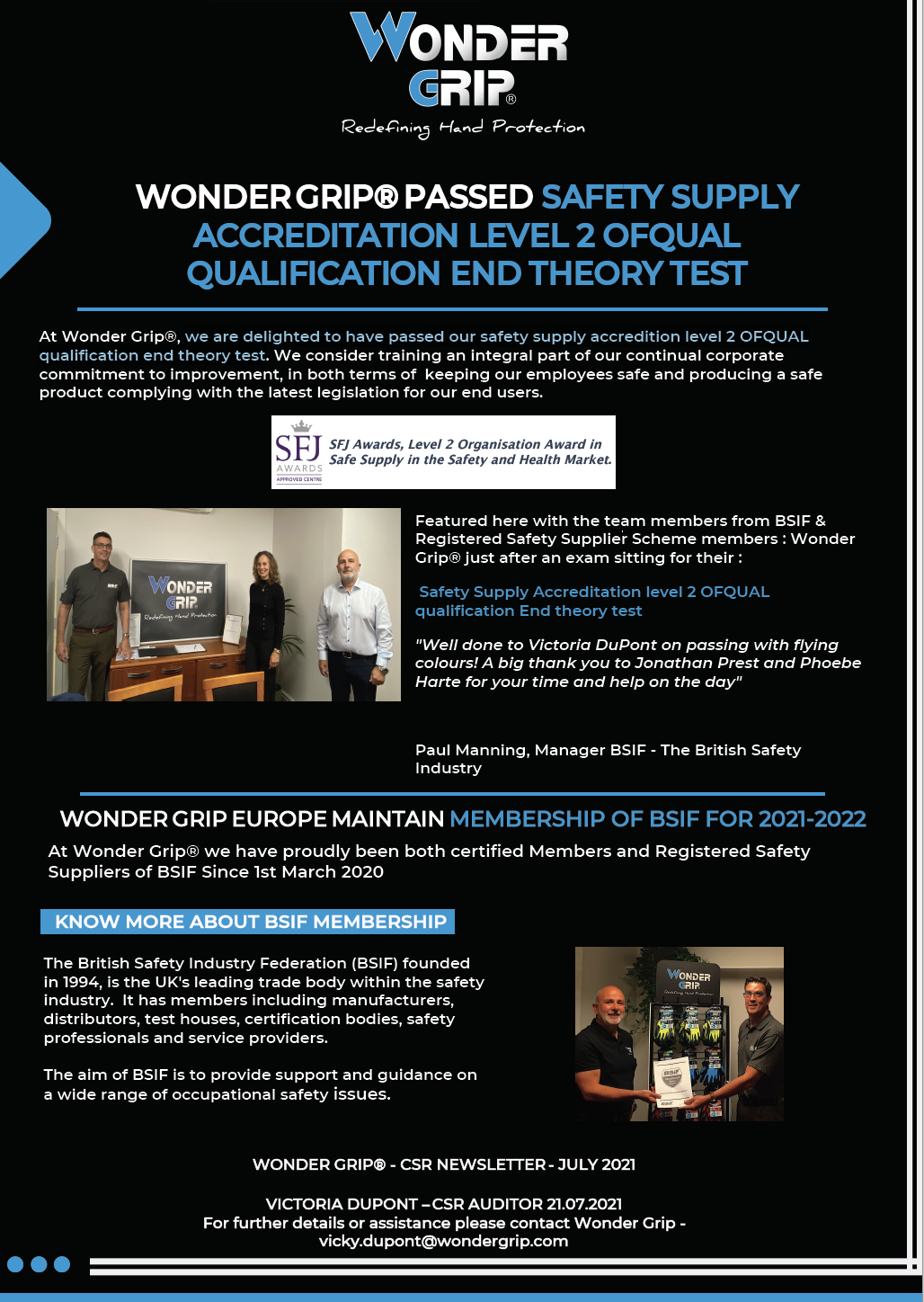

BSIF Member

We are proud to have joined the British Safety Industry Federation (BSIF). As a protective glove manufacturer, innovation, quality control and compliance are our priorities.

&Wider

Wonder Grip prides itself on its open and transparent dialogue with its employees, turning their suggestions into concrete actions. Wonder Grip constantly seeks to improve through its involvement in continuous research.